Page 5 - WIRE-BOND Products Catalog

P. 5

L A D D E R T Y P E W I T H T I E S WIRE-BOND

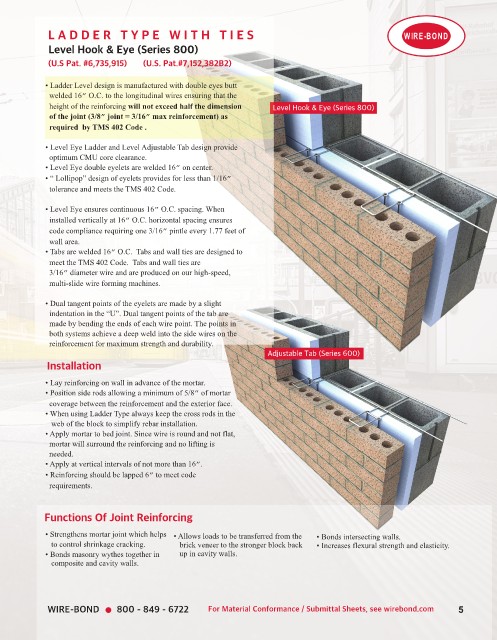

Level Hook & Eye (Series 800)

(U.S Pat. #6,735,915) (U.S. Pat.#7,152,382B2)

(U.S Pat. #6,735,915) (U.S. Pat.#7,152,382B2

• Ladder Level design is manufactured with double eyes butt

welded 16” O.C. to the longitudinal wires ensuring that the

height of the reinforcing will not exceed half the dimension Level Hook & Eye (Series 800)

of the joint (3/8” joint = 3/16” max reinforcement) as

required by TMS 402 Code .

• Level Eye Ladder and Level Adjustable Tab design provide

optimum CMU core clearance.

• Level Eye double eyelets are welded 16” on center.

• “ Lollipop” design of eyelets provides for less than 1/16”

tolerance and meets the TMS 402 Code.

• Level Eye ensures continuous 16” O.C. spacing. When

installed vertically at 16” O.C. horizontal spacing ensures

code compliance requiring one 3/16” pintle every 1.77 feet of

wall area.

• Tabs are welded 16” O.C. Tabs and wall ties are designed to

meet the TMS 402 Code. Tabs and wall ties are

3/16” diameter wire and are produced on our high-speed,

multi-slide wire forming machines.

• Dual tangent points of the eyelets are made by a slight

indentation in the “U”. Dual tangent points of the tab are

made by bending the ends of each wire point. The points in

both systems achieve a deep weld into the side wires on the

reinforcement for maximum strength and durability.

Adjustable Tab (Series 600)

Installation

• Lay reinforcing on wall in advance of the mortar.

• Position side rods allowing a minimum of 5/8” of mortar

coverage between the reinforcement and the exterior face.

• When using Ladder Type always keep the cross rods in the

web of the block to simplify rebar installation.

• Apply mortar to bed joint. Since wire is round and not flat,

mortar will surround the reinforcing and no lifting is

needed.

• Apply at vertical intervals of not more than 16”.

• Reinforcing should be lapped 6” to meet code

requirements.

Functions Of Joint Reinforcing

• Strengthens mortar joint which helps • Allows loads to be transferred from the • Bonds intersecting walls.

to control shrinkage cracking. brick veneer to the stronger block back • Increases flexural strength and elasticity.

• Bonds masonry wythes together in up in cavity walls.

composite and cavity walls.

WIRE-BOND 800 - 849 - 6722 For Material Conformance / Submittal Sheets, see wirebond.com 5