Page 3 - WIRE-BOND Products Catalog

P. 3

G E N E R A L I N F O R M A T I O N WIRE-BOND

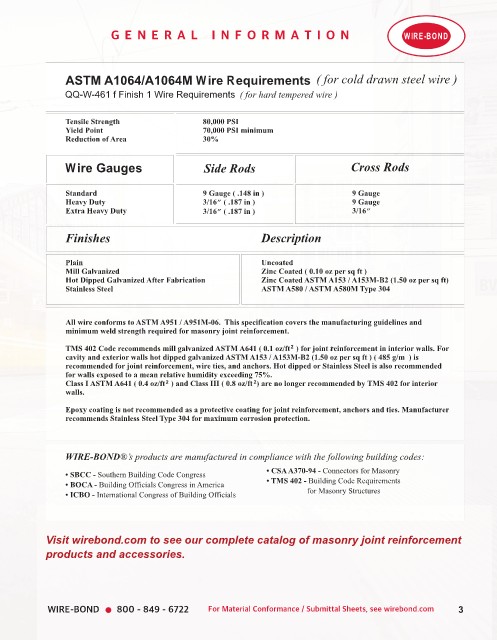

ASTM A1064/A1064M Wire Requirements ( for cold drawn steel wire )

QQ-W-461 f Finish 1 Wire Requirements ( for hard tempered wire )

Tensile Strength 80,000 PSI

Yield Point 70,000 PSI minimum

Reduction of Area 30%

Wire Gauges Side Rods Cross Rods

Standard 9 Gauge ( .148 in ) 9 Gauge

Heavy Duty 3/16” ( .187 in ) 9 Gauge

Extra Heavy Duty 3/16” ( .187 in ) 3/16”

Finishes Description

Plain Uncoated

Mill Galvanized Zinc Coated ( 0.10 oz per sq ft )

Hot Dipped Galvanized After Fabrication Zinc Coated ASTM A153 / A153M-B2 (1.50 oz per sq ft)

Stainless Steel ASTM A580 / ASTM A580M Type 304

All wire conforms to ASTM A951 / A951M-06. This specification covers the manufacturing guidelines and

minimum weld strength required for masonry joint reinforcement.

2

TMS 402 Code recommends mill galvanized ASTM A641 ( 0.1 oz/ft ) for joint reinforcement in interior walls. For

2

cavity and exterior walls hot dipped galvanized ASTM A153 / A153M-B2 (1.50 oz per sq ft ) ( 485 g/m ) is

recommended for joint reinforcement, wire ties, and anchors. Hot dipped or Stainless Steel is also recommended

for walls exposed to a mean relative humidity exceeding 75%.

Class I ASTM A641 ( 0.4 oz/ft ) and Class III ( 0.8 oz/ft ) are no longer recommended by TMS 402 for interior

2

2

walls.

Epoxy coating is not recommended as a protective coating for joint reinforcement, anchors and ties. Manufacturer

recommends Stainless Steel Type 304 for maximum corrosion protection.

WIRE-BOND®’s products are manufactured in compliance with the following building codes:

• CSA A370-94 - Connectors for Masonry

• SBCC - Southern Building Code Congress

• BOCA - Building Officials Congress in America • TMS 402 - Building Code Requirements

• ICBO - International Congress of Building Officials for Masonry Structures

Visit wirebond.com to see our complete catalog of masonry joint reinforcement

products and accessories.

WIRE-BOND 800 - 849 - 6722 For Material Conformance / Submittal Sheets, see wirebond.com 3