Page 10 - fero wirebond catalog

P. 10

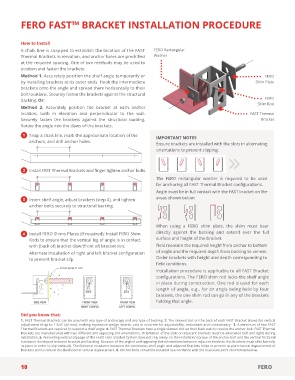

FERO FAST™ BRACKET INSTALLATION PROCEDURE

How to Install

A chalk line is snapped to establish the location of the FAST FERO Rectangular

Thermal Brackets in elevation, and anchor holes are predrilled Washer

at the required spacing. One of two methods may be used to

position and fasten the brackets:

Method 1. Accurately position the shelf angle temporarily or FERO

by installing brackets at its outer ends. Hook the intermediate Shim Plate

brackets onto the angle and spread them horizontally to their

bolt locations. Securely fasten the brackets against the structural

backing. Or: FERO

Shim Rod

Method 2. Accurately position the bracket at each anchor

location, both in elevation and perpendicular to the wall. FAST Thermal

Securely fasten the brackets against the structural backing. Bracket

Rotate the angle into the claws of the brackets.

1 Snap a chalk line, mark the approximate location of the IMPORTANT NOTES

anchors, and drill anchor holes. Ensure brackets are installed with the slots in alternating

orientations to prevent slipping.

2 Install FAST Thermal Brackets and finger tighten anchor bolts.

The FERO rectangular washer is required to be used

for anchoring all FAST Thermal Bracket configurations.

A

Angle must be in full contact with the FAST bracket on the

3 Insert shelf angle, adjust brackets (step 4), and tighten areas shown below:

anchor bolts securely to structural backing.

When using a FERO shim plate, the shim must bear

4 Install FERO Shims Plates (if required); Install FERO Shim directly against the backing and extend over the full

Rods to ensure that the vertical leg of angle is in contact surface and height of the bracket.

with (back of) bracket claw/(front of) bracket slot. Field measure the required height from anchor to bottom

Alternate installation of right and left bracket configuration of angle and the required depth from backing to veneer.

to prevent bracket slip. Order brackets with height and depth corresponding to

field conditions.

FERO SHIM PLATE

Installation procedure is applicable to all FAST Bracket

configurations. The FERO shim rod locks the shelf angle

in place during construction. One rod is used for each

length of angle, e.g., for an angle being held by four

brackets, the one shim rod can go in any of the brackets

holding that angle.

Did you know that:

1. FAST Thermal Brackets can be used with any type of anchorage and any type of backing. 2. The skewed slot on the back of each FAST Bracket allows for vertical

adjustment of up to 1-3/4” (44 mm), making expensive wedge inserts, cast in concrete for adjustability, redundant and unnecessary. 3. A minimum of two FAST

Thermal Brackets are required to support a shelf angle. 4. FAST Thermal Brackets have a single skewed slot on their back web to receive the anchor bolt. FAST Thermal

Brackets are manufactured with two different and opposing slot orientations. Orientation of the slots on adjacent brackets must be alternated (left and right) during

installation. 5. Preventing vertical slippage of the FERO FAST Bracket System does not rely solely on the installation torque of the anchor bolt and the vertical frictional

resistance developed between bracket and backing. Because of the angled and opposing slot orientations between adjacent brackets, the Brackets must slide laterally

in-plane in order to slip vertically. The frictional resistance between the continuous shelf angle and adjacent Brackets helps to prevent in-plane lateral displacement of

Brackets and to reduce the likelihood of vertical displacement. 6. Anchor bolts should be installed in accordance with the manufacturer's recommendations.

10 FERO