Page 8 - fero wirebond catalog

P. 8

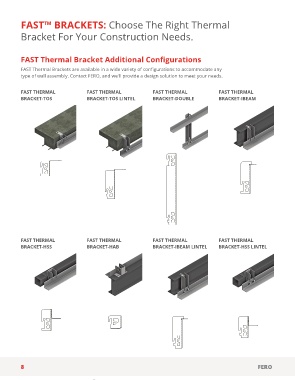

FAST™ BRACKETS: Choose The Right Thermal

Bracket For Your Construction Needs.

FAST Thermal Bracket Additional Configurations

FAST Thermal Brackets are available in a wide variety of configurations to accommodate any

type of wall assembly. Contact FERO, and we'll provide a design solution to meet your needs.

Notes: 1. Design loads are the maximum allowable vertical loads that a FAST Thermal Bracket can support using its standard L4x4x1/4" (L102x102x6mm). Tests used a stiffened backing and

shelf angle in order to isolate FAST Thermal Bracket capacities. Brackets were anchored using a 5/8” (16mm) bolt vertically centred in the bracket slot and a point load was applied 0.79” (20mm)

o/c from the end (toe) of the angle. Tabled allowable loads are (unfactored) service loads, and have been established by test and calculation, and demonstrate a level of safety and performance FAST THERMAL FAST THERMAL FAST THERMAL FAST THERMAL

consistent with North American design standards. Tabled allowable veneer heights are calculated as (maximum allowable vertical load per bracket) ÷ (weight of veneer per unit area x bracket BRACKET-TOS BRACKET-TOS LINTEL BRACKET-DOUBLE BRACKET-IBEAM

spacing). 2. Anchor bolt slip resistance is higher than the stated design loads with proper FAST Thermal Bracket installation. Slots must be alternating and bolts should be tightened to snug

plus half turn. 3. Veneer weights used are: 40lb/ft2 (195kg/m2) for clay brick; 30lb/ft2 (146kg/m2) for 105lb/ft3 (1682kg/m3) lightweight concrete block; 38lb/ft2 (185kg/m2) for 125lb/ft3 (2002kg/m3)

normal weight concrete block; and 45.0lb/ft2 (220kg/m2) for natural stone. 4. The typical FAST Thermal Bracket slots are sized for a 5/8” (16mm) diameter anchor bolt, but brackets can be made

for other anchor bolt diameters upon request. Comply with all manufacturer’s design and installation requirements pertaining to capacity, edge distances, torqueing etc. FERO does not assume

responsibility for the design of the anchorage of the FAST Thermal Brackets. The values shown in this FAST System Load Table assume that the FAST Thermal Bracket is adequately anchored.

5. Where the FAST™ system is designed/intended to support masonry veneer having panel height exceeding 30’ (9.1m), contact FERO for additional design information. 6. The bracket spacing may

vary by ±4” (100mm). 7. Use the FERO Rectangular Washer when installing the FAST Thermal Bracket (required). 8. The FAST System Load Table applies to the FAST Standard, FAST Lintel, and FAST

Inverted. This table will generally apply to the Extended FAST systems and custom FAST Thermal Brackets as well, but additional engineering may be required. Contact FERO for more information.

9. FERO recommends not installing over gypsum sheathing (unless otherwise engineered) as tension from the anchor bolt may crush gypsum sheathing; unrelated to the FAST Thermal Brackets.

FAST THERMAL FAST THERMAL FAST THERMAL FAST THERMAL

BRACKET-HSS BRACKET-HAB BRACKET-IBEAM LINTEL BRACKET-HSS LINTEL

8 FERO

D

C C

C Manufacturing approval by:

Abbreviations Approved by: TM

AT Angle Thickness

C D Depth Material: Size: Dwg no: Rev:

H Height

MB Mounting Bolt C Assembly2

BT Bracket Thickness Mass: N/A Scale: Autodesk inventor file Sheet: 1 Of 1

W Width

1 2 3 4

Legal disclaimer: Legal disclaimer:

FERO FAST™ Bracket

THESE DRAWINGS ARE PROVIDED FOR INFORMATIONAL PURPOSES ONLY FOR DESIGN PROFESSIONALS. ALL RIGHTS FERO FAST™ Bracket

THESE DRAWINGS ARE PROVIDED FOR INFORMATIONAL PURPOSES ONLY FOR DESIGN PROFESSIONALS. ALL RIGHTS RESERVED. ALL WORKS CONTAINED HEREIN ARE OWNED BY FERO CORPORATION AND PATENT PROTECTED. United States Patent US 6,128,883

RESERVED. ALL WORKS CONTAINED HEREIN ARE OWNED BY FERO CORPORATION AND PATENT PROTECTED. United States Patent US 6,128,883

MANUFACTURE IS NOT PERMITTED BY ANY PARTY OTHER THAN FERO CORPORATION. RECIPIENT OF THIS DRAWING MANUFACTURE IS NOT PERMITTED BY ANY PARTY OTHER THAN FERO CORPORATION. RECIPIENT OF THIS DRAWING Canadian Patents CA 2,284,069; CA 2,254,510; CA 2,591,687;

ASSUMES ALL RISK AND LIABILITY FOR ANY LOSSES, DAMAGES, CLAIMS OR EXPENSES RESULTING FROM THE USE OF ASSUMES ALL RISK AND LIABILITY FOR ANY LOSSES, DAMAGES, CLAIMS OR EXPENSES RESULTING FROM THE USE OF CA 2,759,747; CA 2,759,837; and CA 2,759,778 Legal disclaimer:

Canadian Patents CA 2,284,069; CA 2,254,510; CA 2,591,687;

THESE DRAWINGS. THE AUTHOR OF THESE DRAWINGS IS NOT AN ARCHITECT OR ENGINEER.

THESE DRAWINGS. THE AUTHOR OF THESE DRAWINGS IS NOT AN ARCHITECT OR ENGINEER. CA 2,759,747; CA 2,759,837; and CA 2,759,778 Other Patents Pending

Other Patents Pending Drawn by: THESE DRAWINGS ARE PROVIDED FOR INFORMATIONAL PURPOSES ONLY FOR DESIGN PROFESSIONALS. ALL RIGHTS

Drawn by: 2018-12-19 Copyright © 2018 FERO Corporation Engineering 2018-12-19 ENGINEERED MASONRY CONNECTORS RESERVED. ALL WORKS CONTAINED HEREIN ARE OWNED BY FERO CORPORATION AND PATENT PROTECTED.

Engineering

MANUFACTURE IS NOT PERMITTED BY ANY PARTY OTHER THAN FERO CORPORATION. RECIPIENT OF THIS DRAWING

Checked by:

D Copyright © 2018 FERO Corporation Checked by: ENGINEERED MASONRY CONNECTORS D FERO 15305-117 Avenue NW,ENDOMONTON AB, CANADA T5M-3X4 D ASSUMES ALL RISK AND LIABILITY FOR ANY LOSSES, DAMAGES, CLAIMS OR EXPENSES RESULTING FROM THE USE OF

FERO

Tel: (780) 455-5098 Fax: (780) 452-5969

15305-117 Avenue NW,ENDOMONTON AB, CANADA T5M-3X4

Tel: (780) 455-5098 Fax: (780) 452-5969 www.ferocorp.com E-mail: info@ferocorp.com THESE DRAWINGS. THE AUTHOR OF THESE DRAWINGS IS NOT AN ARCHITECT OR ENGINEER.

www.ferocorp.com E-mail: info@ferocorp.com

Title: Manufacturing approval by: Title:

Manufacturing approval by: Approved by: FERO FAST System Copyright © 2018 FERO Corporation

TM

FERO FAST System

Abbreviations Approved by: AT Angle Thickness Abbreviations TM D

AT Angle Thickness D Depth Size: Dwg no: Rev:

D Depth H Height Dwg no: Material: Rev:

Size:

H Height Material: MB Mounting Bolt C Assembly2

C

Assembly2

MB Mounting Bolt BT Bracket Thickness Mass: Scale: Sheet:

Scale:

BT Bracket Thickness Mass: N/A W Width Autodesk inventor file N/A Sheet: 1 Of 1 Autodesk inventor file 1 Of 1 Abbreviations

W Width

D Depth

2 1 3 2 4 3 4 AT Angle Thickness

H Height

MB Mounting Bolt

BT Bracket Thickness

W Width

1 2